What is FDM 3D Printing?

At the consumer level, fused deposition modeling (FDM), commonly referred to as fused filament fabrication (FFF), is the most popular 3D printing technology. FDM 3D printers function by melting thermoplastic filaments like ABS (Acrylonitrile Butadiene Styrene) and PLA (Polylactic Acid) and applying them layer by layer to a build platform through the use of heated nozzles. Until the portion is finished, one layer at a time is applied.

FDM 3D printers are ideal for quick and inexpensive prototyping of simple parts, such as those that would generally be machined, as well as for creating small proof-of-concept models.

How Fused Deposition Modeling Works

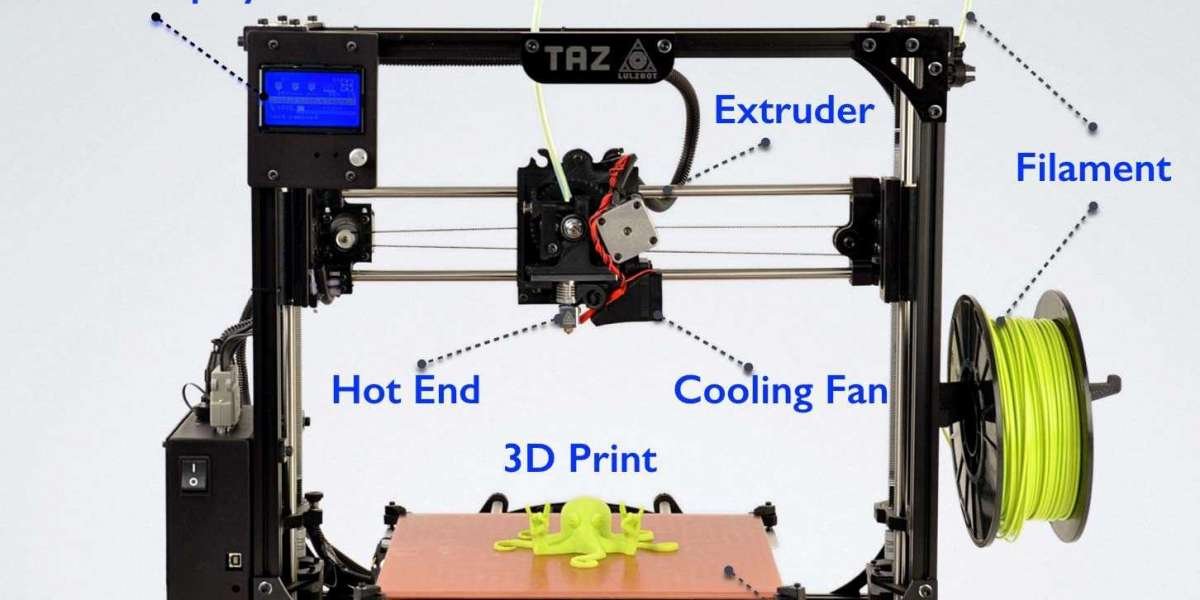

FDM technique uses an extruder to introduce a spool of the selected feedstock into a conventional fused deposition modeling system. The extruder controls how the polymer is fed into the heater, where it melts. This liquid polymer is extruded through a nozzle and put onto the build platform, which is often referred to as the print bed. The printhead, which is linked to a gantry above the flat build platform, houses the extruder, heater, and nozzle. As the material is deposited, this is intended to provide a significant amount of freedom of motion in the X and Y axes.

The fused deposition modeling technology divides a 3D computer-aided design (CAD) file into discrete slices, or cross-sections, using cutting-edge printer software. In order to establish the path the printer head must take across the X and Y axes to deposit the initial layer of material onto the build platform, each slice in the file is translated into machine code, which essentially employs the Cartesian coordinate system. Following the completion of the bottom layer, the build platform is lowered by a tiny amount, proportionate to the thickness of the layer that was deposited, and the printhead continues the procedure to deposit the second layer. The portion is completed by repeating this process in a series of layers.

The majority of FDM systems include a two-nozzle setup that allows them to selectively extrude support structures as they print parts. This support might dissolve in a sodium hydroxide (NaOH) solution depending on the feedstock, leaving only the printed component behind after processing. The printed element can also be manually removed from the support framework without causing any harm.

This method has numerous advantages, especially when it comes to creating rapid prototypes and concept models for research and design (RD) procedures.

Why Use FDM For Your Parts?

Fused deposition modeling (FDM) is among the most easily accessible and recognizable additive manufacturing technologies worldwide. Available to both 3D printing hobbyists and large-volume manufacturers alike, it is known for its speed and precision in generating three-dimensional polymeric structures using a choice of feedstock materials. The range of filaments available for fused deposition modeling includes:

- Acrylonitrile butadiene styrene (ABS-M30, ABS-M30i, ABSi)

- Acrylonitrile styrene acrylate (ASA)

- Polycarbonates (PC, PC-ABS, and PC-ISO)

- High-performance plastics (PPSF, Ultem 1010, Ultem 9085, and Nylon-12)

Benefits Of Fused Deposition Modeling

A cost-effective additive manufacturing method is FDM printing, particularly for quick prototyping or low-volume production. FDM prints have short lead times from bid to print and delivery because they require minimum post-processing and employ more readily accessible materials.